Vented roofs work, and are the best solution to eliminate many issues that appeared when we started to insulate buildings - 'leaks' caused by condensation, mold, water damaged sheathing and ice dams.

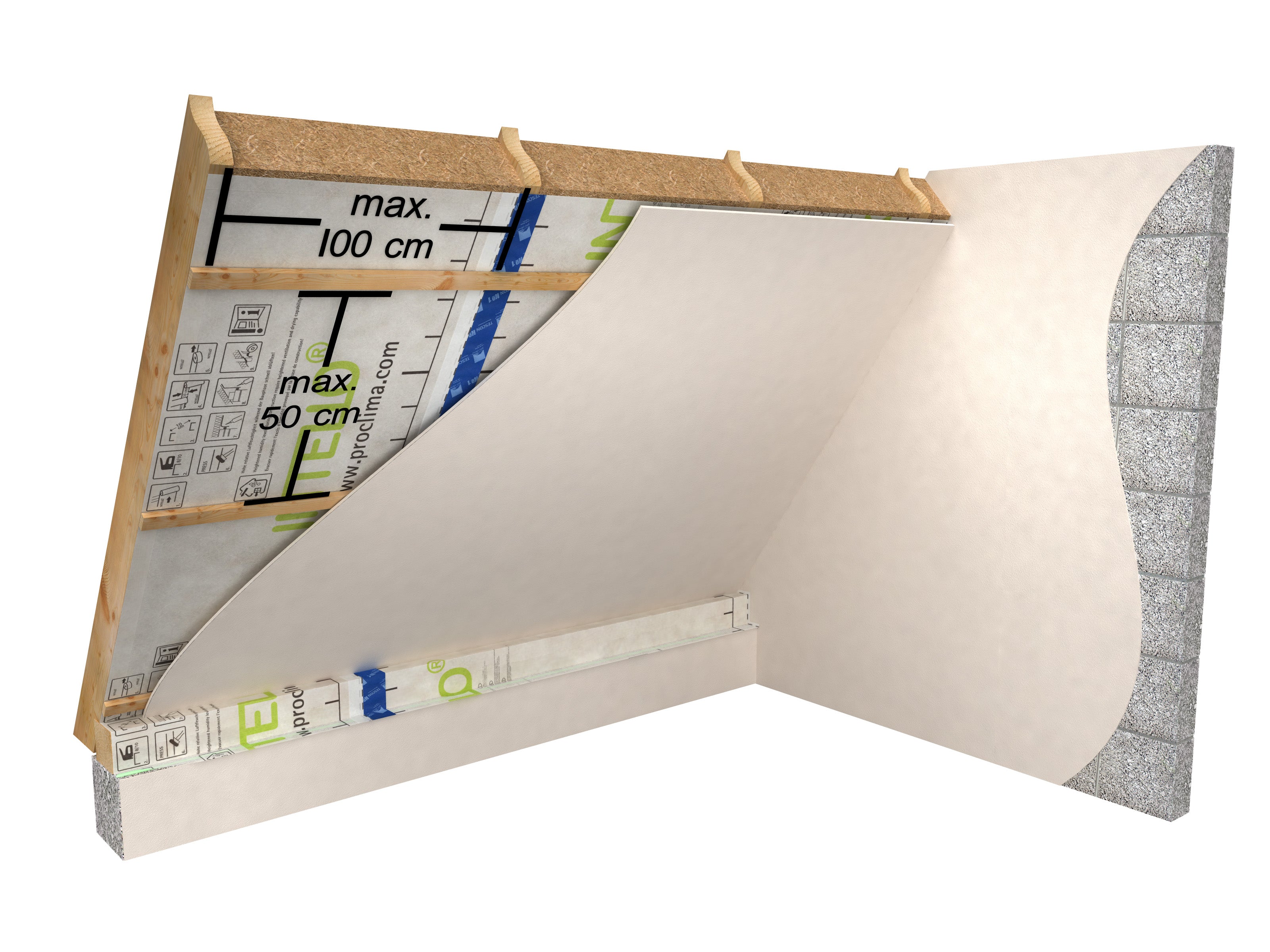

Airtight intelligent vapour control layer - INTELLO - installed on the interior of the roof beams

What causes all these problems? Most of these issues in mixed and cold climates are related to the hot, somewhat humid interior air rising up, and eventually hitting a cold surface - at that point it condenses and will make your structure wet. So how can we keep the inside of our roofs dry?

Step one to prevent this problem from occurring, is to make your ceiling absolute airtight - a service cavity will enable you to enjoy this air-tightness over the long term. The airtight layer will keep the interior of the house comfortable and prevents any of the conditioned air from escaping upward - saving energy and it is a crucial first step to prevent condensation from occurring during cold weather.

Roof with SOLITEX MENTO membrane, vertical and counter battens for venting.

A second general rule to prevent condensation, is that one would like interior materials that have a permeance that is 5 times lower than the exterior materials (a minimum 5:1 ratio*). This to facilitate outward drying of the assembly during the times of the year when it is colder outside then inside (which is the large majority of the year as nights in April, May and September, October even have these conditions). When conforming to these rules for vented roofs, one can in general omit WUFI calculations.

Questions: if exterior sheathing plywood has a perm rating of 1, what does this rule then require your vapour retarder to be ..... below 0.2 perms (INTELLO does conform to this rule) - but to reduce the chance of condensation and to create a more robust assembly with a higher drying potential, it would be very beneficial to design an assembly with more vapour open materials on the exterior.

Special considerations are needed for the conventional USA roof that is made with the lowest roofing material cost - asphalt shingles. These shingles are vapour closed when nailed to the sheathing - since this will lead to all issues mention above, a host of solutions have been proposed (finehomebuilding article)- all to prevent condensation of moist/warm interior air below the asphalt singles.

A factor 5 difference - between a airtight and a windwashed assembly - Institute fuer Bauphysik.

The principal idea employed in that article is to wash the underside of the sheathing with cold and dry air, turning the assembly into a vented roof. It should be quite clear this means we are heating the outside (bringing cold air in to cool/dry warm humid air under the roof sheathing that would otherwise condense) or at least wind-washing the fibrous insulation - even when using venting channels (see David Meiland and Martin Holladay's comments at JLC forum post and the translated German article about vapour open roofs). The venting of these roofs short out the insulation that was installed. The Institute for Bauphysik study above shows the effect of airleaks and the result is that the insulation will be about 5 times less effective (see also the explanation in vented rainscreen blogpost) and thus the building is not performing as well as it could have - wasting energy, fuels and money as long as this situation exists.

Vented roof installation in Wi from BLDGTYP-blog. Note that the roof no longer has foam on top (as their earlier blogpost showed), so the roof can really vent and dry outwards

So if we don't want to heat the outside, and still vent the roof there are a variety of options. We recommend to use an actively vapour open membrane - SOLITEX MENTO - over the insulation - with a high perm rating that exceeds 30. The drying potential of the vented roof now can be assured as the 1:5 is complied with a large margin - it even allows OSB/plywood to be used as an airtight layer in most cases. And when exterior sheathing/bracing is required, it would be highly recommended to use vapour open boards (solid wooden decking or USG securock, Celotex) below the membrane.

vapour open subroof with SOLITEX MENTO and battens and counter battens for drainage, venting and roof application

Or we can eliminate sheathing altogether and using vertical battens and counter battens/plywood over the membrane to vent the roof (see image on the right). In both cases the insulation is protected on all 6 sides and thus optimized:

-

a smart vapour retarder (INTELLO) or plywood/OSB on the interior - taped as an airtight layer - assures inward drying in summer.

-

a fibrous insulation in-between (ideally hygroscopic - ie cellulose, cotton, wool - to help manage any humidity or moisture that will occur)

-

a vapour open exterior build up - membrane (subroofing for extra waterproofing) and sheathing have a perm rating that is more than 5 times higher than the interior retarders perm - facilitates drying to exterior in cold weather/nights.

-

a vented space under the roofing material (metal, tiles or plywood + asphalt singles).

Additional information regarding application of the SOLITEX MENTO membranes can be found in the SOLITEX system brochure.

SOLITEX MENTO vapour open membrane, Chris Corson (Ecocor.us) is walking over hor. roof battens. Photo: Naomi C Beal

* this ratio is per German DIN 4108-3 regulations, Pro Clima manufacturer guidance, and US DOE guidance